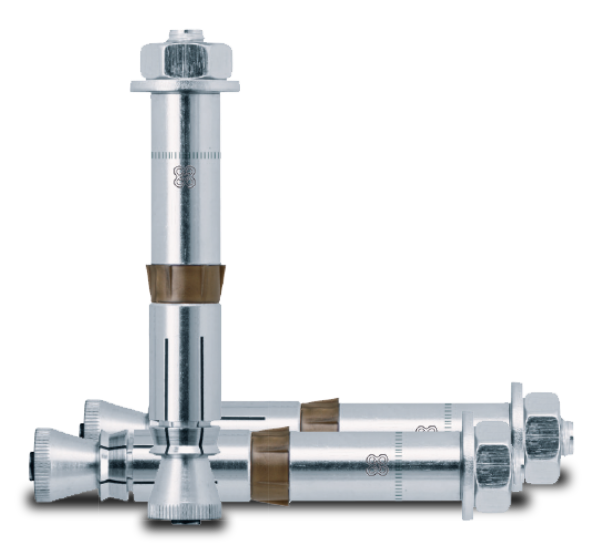

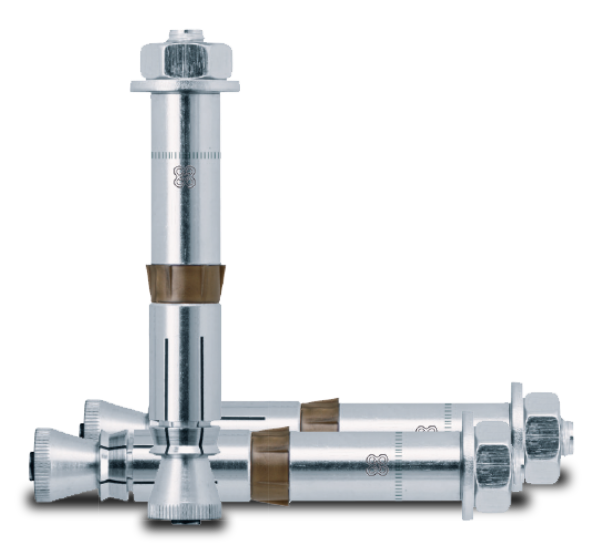

Superplus M8 - M16

Liebig Superplus is an automatic self-undercutting fixing system that does not require a special fixing tool. European Technical Approval Option 1.

Liebig Superplus is an automatic self-undercutting fixing system that does not require a special fixing tool. European Technical Approval Option 1.